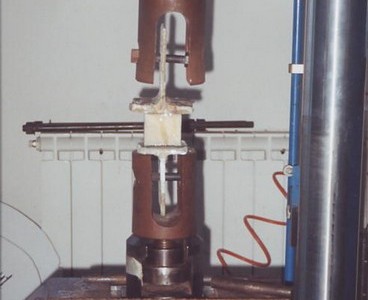

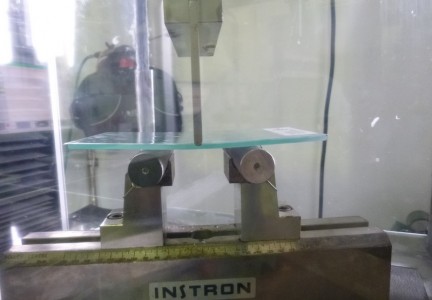

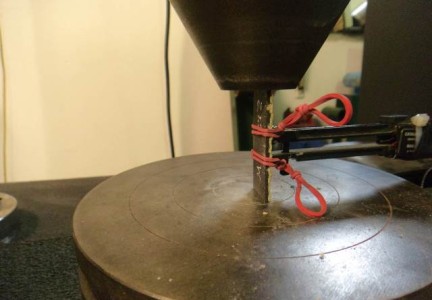

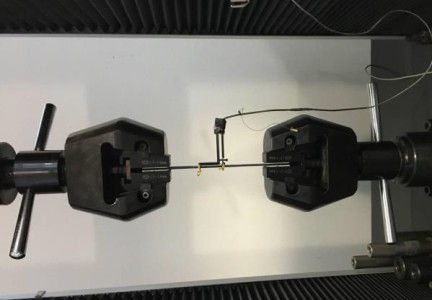

Mechanical and technological tests on plastic and other composite materials

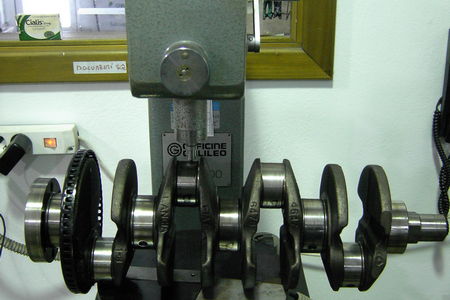

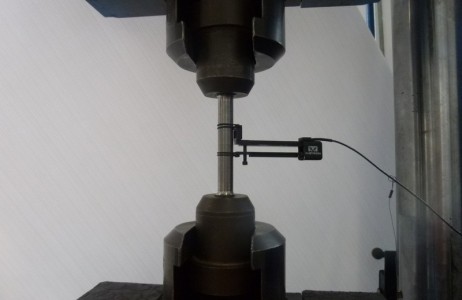

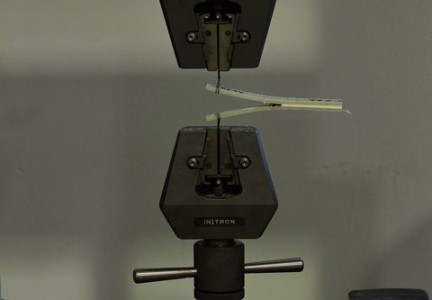

Our Laboratory is able to carry out tests, checks and tests on materials used in the field of plastic base composites such as resins, reinforcing fibers, thermoplastic foams for making sandwiches and also on finished products such as monolithic laminates made with different types of reinforcement ( glass, kevlar, carbon fiber) on sandwich laminates with cores in thermoplastic material, balsa, honeycomb structures in light alloy or polymeric. The equipment and equipment available at the Mechanical Testing Department allow to perform tests for the mechanical characterization of composite laminates such as:

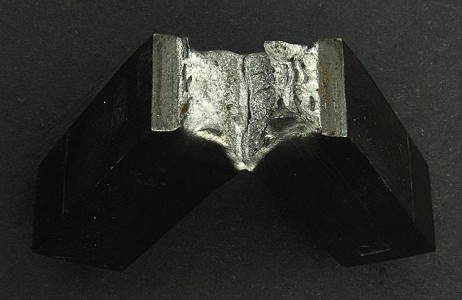

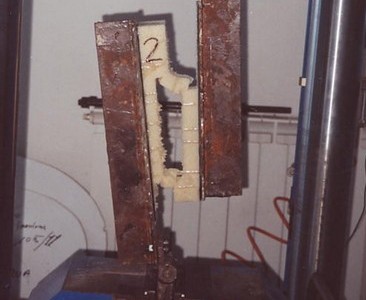

- Tensile tests – Bending tests – Compression tests – Interlaminar cutting tests – Cross cutting tests – Sandwich cutting tests – Sandwich bending tests – Cutting tests on adhesives – Peel tests on adhesives

The Laboratory is also equipped with equipment and equipment such as:

- Thermostatic chambers – Cold rooms – Ventilated treatment furnaces – Dive tanks in chemical products and diesel oil

to conduct tests on material after conditioning or aging in fluids.